Fuel-Operated Coolant Heaters for the Fracking Industry

Posted by [email protected] on 25th Jun 2025

Heatso supplies a wide range of fuel-operated coolant and air heaters engineered for demanding applications across the oil, gas, and coal industries - including extensive use in hydraulic fracturing (fracking) operations.

Fuel-Operated Coolant Heaters for the Fracking Industry

Heatso supplies a wide range of fuel-operated coolant and air heaters engineered for demanding applications across the oil, gas, and coal industries - including extensive use in hydraulic fracturing (fracking) operations. These heaters are essential in keeping expensive fracking equipment operational in low temperatures and remote field environments.

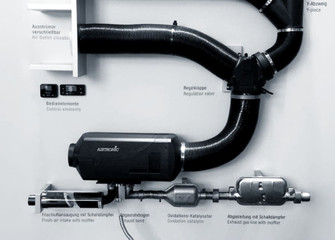

A diesel-fired heater is typically the core component of a larger system used for frac heating, often referred to as a frack heater. These systems can also be used as a frac tank heater (frac water heater). This guide explains how diesel coolant heaters are used in the fracking industry, which models are best suited, and why preheating and temperature control are critical for frac equipment reliability and performance.

Applications of Coolant Heaters in Hydraulic Fracturing Equipment

In modern hydraulic fracturing operations, fuel-operated heaters are used across a wide range of mobile and stationary equipment. Their role is to preheat engine coolant, or heat coolant that is used within a larger system, hydraulic oil, DEF systems and other components and to maintain optimal working temperatures in freezing or fluctuating climates.

Common frac site equipment that uses diesel fired heaters includes:

- Frac pump trailers

- Blender units

- Hydration systems

- Chemical injection skids

- Sand conveyor systems

- Mobile data centers and crew cabins

- Diesel generator trailers

- Other fracking equipment

24V vs. 12V Coolant Heaters in the Fracking Sector

Most large fracking machinery operates on 24-volt electrical systems, which are standard in high-horsepower diesel engines used in frac pumps, blenders, and support units.

24V heaters are mostly used for:

- Frac pump trailers (2,000+ HP)

- Blender units

- Hydration and chemical skids

- Mobile command and data acquisition systems

12V systems may still be found in:

- Older trailers or retrofitted equipment

- Light-duty support vehicles

- Control cabins and auxiliary skids

There are always many trucks on the site that will often have fuel-operated engine heaters to preheat their engines - it is the same type of diesel fired coolant heater that can be either 12V and 24 Volt.

Recommended Coolant Heaters by Voltage and Output

24V diesel coolant heaters are widely used across hydraulic fracturing operations to preheat engines, coolant circuits, DEF systems, hydraulic tanks, and frac fluid heating systems in general. The appropriate BTU rating depends on the total fluid volume, ambient temperature range, engine size and other requirements.

Higher BTU heaters - such as models rated above 100,000 BTU - are typically selected for large diesel engines and high-demand hydraulic or coolant loops, while compact models under 30,000 BTU are used for DEF tanks, battery compartments, or small enclosures.

This below tables should help equipment managers and service technicians compare heater output options when selecting a heating solution for fracking and oilfield applications.

24V Heavy Duty Coolant Heaters

| Heater Model | BTU Output Approx. |

120,000 | |

109,000 | |

102,000 | |

78,500 | |

54,600 | |

54,600 | |

41,000 | |

31,000 | |

Webasto Coolant Heater Thermo Top Evo / C | 17,000 |

17,000 |

12V Heavy Duty Coolant Heaters

| Heater Model | BTU Output Approx. |

78,500 | |

54,600 | |

41,000 | |

17,000 | |

31,000 | |

Eberspacher Hydronic S3 D6L (12V) | 17,000 |

Replacing an Existing Coolant Heater in Fracking Equipment

If you're replacing a coolant heater in your existing frac heater system, there's a high chance the existing unit is a Webasto DBW heater, Eberspacher Hydronic heater, Spheros coolant heater, or Valeo coolant heater. These are some of the most commonly used brands in the oil and gas industry for diesel-powered preheating systems. Also, these are the most reliable and trusted brands when it comes to coolant heaters so we recommend sticking with them.

Heater Compatibility

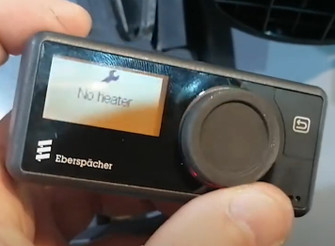

In many cases (not always!), Webasto water heaters, Spheros, and Valeo heaters are mechanically and electrically interchangeable. Eberspacher (also known as Espar in North America) may have slightly different mounting configurations, wiring, or control systems, but replacement is still often possible with minor adjustments. Please note, when you use a different brand heater to replace your old one, accessories like timers may not work since the heaters will have different ECUs in most cases.

When selecting a replacement heater for your fracking rig or other equipment, always verify:

- Voltage (12V or 24V)

- Heat output (BTU/hr or kW) - depending on the application, you can use a slightly more or less powerful unit

- Mounting layout - can be adjusted

- Coolant hose sizes

- Control interface compatibility (manual, digital, CAN, etc.)

Older heater models like Webasto DBW 2010 and DBW 2016 are harder to get, but they can be replaced with other models.

Coolant Circulation Pump Compatibility

These heaters often use the same or interchangeable coolant circulation pumps. The most commonly used pumps in this class are often compatible across brands - but you must ensure that:

- Technical parameters like flow rate, voltage, and maximum pressure match the original unit

- The plug type is not always a limiting factor - it is possible to modify or re-wire them and we can see that it is a common practice in field installations and retrofits.

Repairing an existing heater in Fracking equipment heating system

Heaters used in the oil and gas industry are expected to be true “workhorses” - built to run reliably and continuously under demanding conditions. However, it’s normal for certain components to wear out over time. Heatso offers expedited delivery for many heater parts, however, even that one day downtime may be too much. That’s why it’s recommended to keep backup parts on hand for the components that are most prone to wear. We asked our customers which parts they consider essential, and we’re sharing that list below:

- Circulation pump

- Control Unit for DBW 160 / 230 / 300 / 350 / 2012 / 2016 / 2020 - for 12V applications

- Control Unit for DBW 2010 / 2020 / 300 / 350 - for 24V applications

- Flame sensor for DBW 230 / 300 / 350 / 2010 / 2016 / 2020 / 470

- Fuel Filter

- Fuel pumps

Diesel Engines Used in the Fracking Industry

Coolant heaters are most commonly installed on high-horsepower diesel engines that power critical fracking equipment. These engines are often difficult to start and maintain in cold weather without preheating systems.

Engines found in frac pump trailers (2,000–3,000 HP):

- Caterpillar 3512C / 3512C HD / 3512E

- Caterpillar 3516

- Cummins QSK50 / QSK60

- Cummins QST30

- MTU 12V4000 / 16V4000

Engines in blender units, hydration systems, and skids:

- Caterpillar C15 / C18

- Cummins QSX15 / QSB6.7

- Detroit Diesel Series 60 (legacy)

Support trailer and auxiliary equipment:

- Diesel gensets, small CAT or Cummins blocks

- Wireline trucks, DEF systems, control vans

Why Use Fuel-Operated Coolant Heaters in Fracking Operations?

Fracking operations often take place in remote locations with limited power access and extreme weather. Heating systems that use heavy duty diesel coolant heaters provide essential thermal management, allowing equipment to run more efficiently, start reliably, and reduce costly downtime.

Key benefits include:

- Cold starts become warm start which results in reduced engine wear

- Reliable fluid flow in freezing temperatures

- Fluids freeze prevention

- Improved safety and uptime across the fleet

Heatso: A Trusted Supplier of Heaters and Heater Parts for Frac Equipment

Heatso is a trusted supplier of Webasto, Eberspacher, Espar, Spheros and DBW coolant heaters designed for the oil, gas, and coal industries that require high heat output. We support both 12V and 24V systems with high-output models up to 120,000 BTU/hr - including the DBW 160, Thermo Plus 300, and Thermo Plus 350 and other heaters that are engineered for extreme-duty applications.

We also offer expedited shipping service for many of our heating systems and heater parts.